https://sailtortuguita.blogspot.com/2023/12/parallel-or-series.html

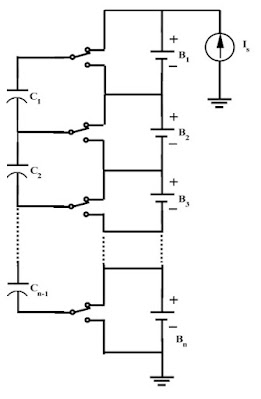

For a small battery bank, like 100 Amp hours (Ah), you can put four 3.2 volt, 100 Ah cells together in series to get a 12 volt 100Ah bank like shown below. If you need more capacity, you can put another bank in parallel with the first to give 12 volt 200Ah.

|

| 4S2P with multiple Daly BMS |

These type of BMS's use FET transistors to shut off charging or discharging protecting the cells. In theory, if all 5 banks are perfectly equal, each bank will share the load with every other. If for example, your fridge draws 20 amps, each bank would provide 4 amps. Like any DC system in parallel, like alternators, batteries, or solar panels, there are small differences and imbalances occur.

So you may even have all 20 amps being provided from one bank with the others providing nothing. That's worst case but they never balance out.

There is not a BMS that exists that would solve this problem but one could be made if it had network communication between and PWM output from each and every BMS so that they can all coordinate and output the same power. Unfortunately nobody make such a thing.

The FET transistor switches of these small BMS's, like any transistor, have maximum power ratings and are destroyed by heat. I do not think it is prudent to trust the health of your boat's electrics to a possibly under-rated cheap Chinese transistor. Unbalance between the BMS outputs may very well cause a single FET maximum current rating to be exceeded sooner than expected.

An example I saw was that a friend had his banks 'either/or'. One bank would put out all the power until it's voltage was low enough that it would then be taken over by the other bank which would then put out all the power. This would go back and forth until they needed to be recharged. Rinse, repeat.

I would think what happens on the charging mode is similar except, if a cheap Chinese FET fails to cut off the charging source, that's when you could get a fire.

One last thing that I have seen with series is that one battery acts as a charging source for the other. The power goes back and forth between the parallel banks and some capacity gets lost as heat to the balance shunts. So if you let these sit for extended periods, you could come back to your boat with discharged batteries.

We installed a 12 volt, 1000 Ah system made up of 40 3.2v 100Ah cells. To do this as a series first parallel second system would need 10 BMS's at $150 each and have all the problems described above. The nomenclature for this would be 4S10P. That means 4 in series first and 10 of those in parallel second.

So, what to do? Go with Parallel first and Series second. That would be 10P4S.

|

| These are our 40 cells as 10P4S |

The good thing with Parallel first is that all the parallel cells stay balanced, they have to stay balanced because they are all connected together. Then you only have 4 series banks that need to be balanced by the BMS.

So,

the BMS is connected to each 3.2v 1000 Ah bank. Each of these banks are kept in

balance by the BMS which reads the individual bank voltages and trips the

appropriate relay for charge or discharge protection.

Since the BMS needs a very good way to shut off charging and discharging, FET transistors are a very bad choice. Relays are a much better and reliable choice. They can handle much more power and can be manually switched in an emergency. I chose the Blue Sea ML-RBS 7700. They can handle 500 Amps continuously and will handle 300 Amps while switching. I will never be able to supply or discharge that much current on our boat.